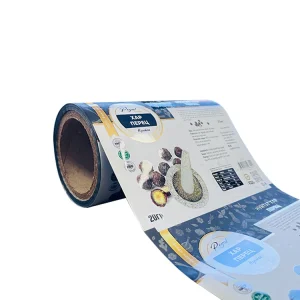

Aluminum Plastic Food Packaging Film Roll for Snack Manufacturers in the USA

The Growing Demand for Flexible Food Packaging in the United States

In recent years, the American food industry has undergone a significant shift toward flexible packaging solutions. Snack manufacturers, co-packers, and private-label food brands are increasingly adopting aluminum plastic food packaging film rolls due to their high barrier properties, cost efficiency, and versatility. This packaging format allows businesses to maintain product freshness while optimizing their packaging operations for speed and sustainability.

As consumer preferences evolve toward convenience and eco-friendliness, flexible laminated films are becoming the go-to choice for packaging taro chips, potato chips, tomato snacks, nuts, coffee, and dry foods. For U.S. importers and distributors, sourcing reliable aluminum plastic food packaging film rolls ensures a competitive edge in both quality and presentation.

What Is Aluminum Plastic Food Packaging Film Roll?

An aluminum plastic food packaging film roll is a multilayer laminated film composed of aluminum foil and high-quality plastics such as PET, BOPP, CPP, or PE. This construction combines the strength and barrier of metalized films with the flexibility and sealing performance of plastics. The result is a material that protects products from oxygen, moisture, light, and odors—key factors in preserving snack quality and extending shelf life.

The roll-stock format makes it ideal for form-fill-seal (FFS) machines and other automated packaging systems widely used in American snack factories. These films can be tailored for pillow bags, stand-up pouches, sachets, and even vacuum-sealed packaging for bulk items.

Key Features and Technical Benefits

High Barrier Protection – The aluminum foil layer provides excellent defense against oxygen, moisture, and UV light.

Enhanced Shelf Appeal – Smooth surface and custom printing options make the packaging visually striking on retail shelves.

Lightweight and Cost-Efficient – Lower shipping costs compared to rigid packaging alternatives.

Superior Seal Strength – Perfect heat sealing ensures leak-proof pouches suitable for chips, coffee, and spices.

Food-Grade Materials – Complies with FDA and EU food contact standards.

Eco-Friendly Options – Available in recyclable or biodegradable film structures to meet sustainability goals.

Typical film combinations include PET/AL/PE, BOPP/VMPET/CPP, and Nylon/PE, offering flexibility for different product needs and machinery types.

Applications of Aluminum Plastic Film Rolls

This versatile packaging material can be used across various sectors:

Snack Foods: Potato chips, taro chips, tomato chips, popcorn, and nuts

Dry Foods: Rice, flour, cereal, coffee, and tea

Powder Products: Spices, drink mixes, protein powders

Frozen Foods: Dumplings, seafood, and frozen vegetables

Pharmaceuticals and Pet Foods: Safe and compliant with barrier and hygiene requirements

For U.S. buyers, aluminum plastic film rolls provide the durability and performance necessary for large-scale production and nationwide distribution.

Why American Buyers Prefer Aluminum Plastic Film Rolls

1. Excellent Product Protection

The multi-layer structure ensures maximum protection from external factors like humidity and air, preventing oxidation and flavor loss. This is crucial for the U.S. snack industry, where freshness drives customer loyalty.

2. Customization Flexibility

Film rolls can be printed in up to 10 colors using advanced rotogravure printing technology. You can add your logo, nutrition facts, and product imagery to build a unique brand identity.

3. Compatibility with Automated Packaging Machines

The films are compatible with vertical form-fill-seal (VFFS) and horizontal form-fill-seal (HFFS) machines used by snack producers across the United States.

4. Cost Savings

The lightweight film material reduces transportation costs while maintaining the integrity of the packaging. It’s a cost-effective option for bulk snack and dry food production.

5. Eco-Conscious Packaging Choice

With growing environmental awareness, U.S. snack manufacturers are shifting to recyclable or partially compostable laminated films that still deliver barrier protection.

Long-Tail Keywords Optimized Throughout

This article naturally includes 7 procurement-oriented long-tail keywords to target U.S. search intent:

aluminum plastic food packaging film roll supplier USA

high barrier food packaging film for snacks

custom printed aluminum film roll

flexible snack packaging material manufacturer

laminated aluminum plastic film roll for chips

roll stock for form fill seal packaging

food grade laminated film manufacturer

These terms align with typical Google searches from procurement managers, importers, and packaging buyers in the U.S. market.

Quality Assurance and Food Safety Compliance

Every aluminum plastic film roll is manufactured under strict quality control systems such as ISO9001 and BRC Global Packaging Standard. The materials meet FDA food contact regulations, making them safe for snack, beverage, and dry food packaging.

Before shipment, all rolls undergo multiple testing processes, including:

Heat-seal strength testing

Barrier property evaluation (oxygen & moisture)

Optical and thickness inspection

Lamination and adhesion testing

This ensures every roll meets the performance standards expected by international buyers.

Customization Options for U.S. Clients

Buyers can tailor every detail of their packaging:

Film Structure: PET/AL/PE, BOPP/CPP, or customized compositions

Thickness Range: 50–150 microns

Roll Width: 100mm–1200mm

Surface Finish: Glossy, matte, or metalized

Printing: Up to 10 colors, food-safe inks

Packaging Type: Roll stock, preformed pouches, or sachets

By partnering with a professional manufacturer, you can receive ready-to-use roll films optimized for your product and packaging line.

Sustainability and Recycling Efforts

In response to environmental regulations and consumer demand in the U.S., suppliers now offer recyclable aluminum-plastic laminates and mono-material PE or PP films. These eco-friendly alternatives provide a balance between performance and environmental responsibility.

Choosing sustainable packaging not only improves your brand image but also helps comply with U.S. state-level packaging sustainability laws.

How to Choose the Right Film Roll Supplier in the USA

When sourcing aluminum plastic food packaging film rolls, consider the following:

Material Quality and Certification – Ensure compliance with FDA and ISO standards.

Customization Capabilities – Ability to provide printed rolls and different laminate structures.

Production Capacity – To support bulk orders and consistent lead times.

Technical Support – Assistance in machine compatibility and product testing.

Sustainability Commitment – Availability of recyclable or biodegradable options.

If you’re ready to upgrade your snack packaging, visit our Product Page for detailed specifications or Request a Quote today.

The Future of Flexible Food Packaging in the U.S.

With more consumers seeking freshness, portability, and eco-conscious options, flexible packaging continues to dominate the food industry. The aluminum plastic food packaging film roll is a cornerstone of this movement, offering unmatched protection and visual appeal for a wide range of snacks and dry foods.

As automation, sustainability, and customization define the next era of food packaging, U.S. manufacturers partnering with reliable suppliers will remain at the forefront of innovation.

For more information, explore our Home Page to learn how our flexible packaging solutions can help your brand grow in the competitive U.S. snack market.

Conclusion: Partner with a Trusted Flexible Packaging Supplier

Whether you’re packaging taro chips, popcorn, coffee, or dry food mixes, the aluminum plastic food packaging film roll delivers superior performance and aesthetic appeal. It’s a proven, cost-efficient solution trusted by top snack manufacturers worldwide.

Get in touch today to discuss your custom packaging project and receive professional support from an experienced team dedicated to the U.S. market.